Boosting Efficiency: The Impact of AMS Factory Automation de Mexico

Introduction

In the highly competitive landscape of modern manufacturing, efficiency is key to staying ahead. Companies are constantly seeking ways to streamline operations, reduce waste, and optimize productivity. AMS Factory Automation de Mexico is playing a pivotal role in this quest by providing innovative automation solutions that significantly boost efficiency across various industries. This article explores the impact of AMS Factory Automation de Mexico on manufacturing efficiency and how their cutting-edge technologies are transforming industrial operations.

Background

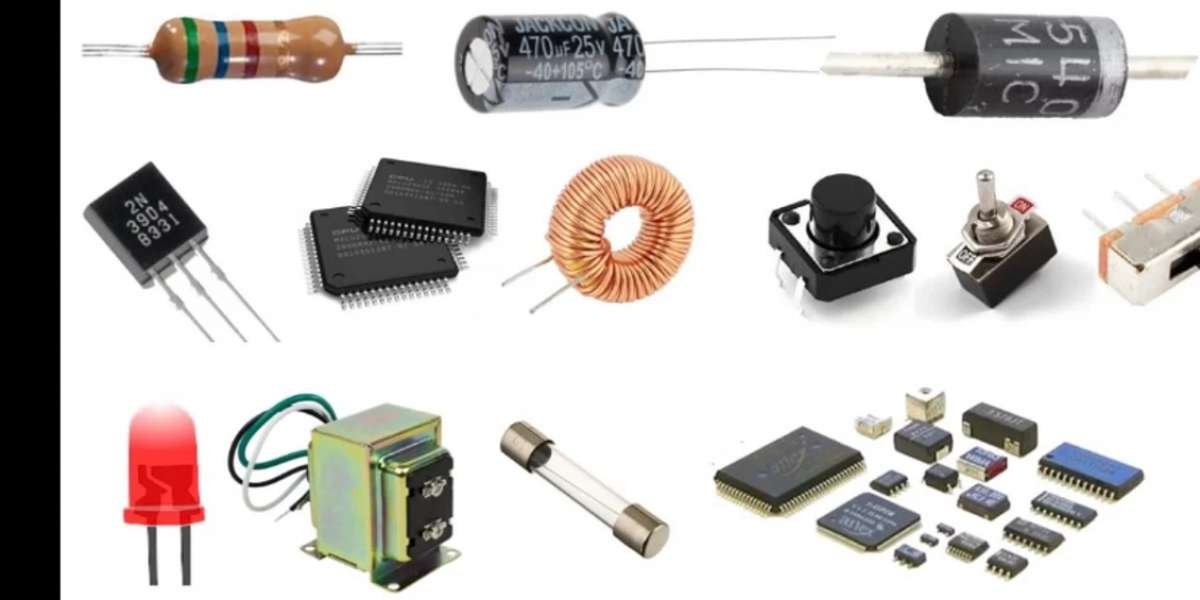

AMS Factory Automation de Mexico specializes in delivering advanced automation solutions tailored to the unique needs of its clients. With a deep understanding of the challenges faced by manufacturers, AMS offers a range of products and services designed to enhance operational efficiency. These solutions are implemented across industries such as automotive, electronics, consumer goods, and more, making AMS a trusted partner for businesses looking to optimize their manufacturing processes.

Efficiency in manufacturing is not just about speeding up production; it’s about doing more with less—using resources wisely, minimizing waste, and maximizing output. AMS Factory Automation de Mexico is at the forefront of this drive, helping manufacturers achieve higher levels of efficiency through automation, robotics, and smart data analytics.

Key Solutions Boosting Efficiency

Automation and Robotics

One of the most significant ways AMS Factory Automation de Mexico boosts efficiency is through the implementation of automation and robotics. By automating repetitive and labor-intensive tasks, AMS helps manufacturers reduce manual errors, speed up production, and lower labor costs. The company's advanced robotic systems are designed to work seamlessly within existing production lines, offering precision, consistency, and the ability to operate continuously without fatigue. This not only increases the speed of production but also ensures that quality is maintained throughout the process.Integrated Control Systems

AMS’s integrated control systems are another critical component in boosting efficiency. These systems provide centralized control over various aspects of the manufacturing process, allowing for real-time monitoring and adjustments. With the ability to quickly respond to changes in production demands or potential issues, AMS’s control systems help prevent downtime and ensure that operations run smoothly. This level of control and responsiveness is essential for maintaining high levels of efficiency in dynamic manufacturing environments.Smart Data Analytics

Data is a powerful tool for improving efficiency, and AMS Factory Automation de Mexico leverages smart data analytics to optimize manufacturing processes. By collecting and analyzing data from across the production line, AMS’s solutions provide insights into performance, resource utilization, and potential bottlenecks. Manufacturers can use this information to make informed decisions that enhance efficiency, such as adjusting workflows, reallocating resources, or identifying opportunities for process improvements. The result is a more streamlined, efficient operation that maximizes output and minimizes waste.Energy Efficiency and Sustainability

AMS Factory Automation de Mexico is also focused on improving efficiency through energy management and sustainability. The company’s solutions are designed to optimize energy usage, helping manufacturers reduce their energy costs and minimize their environmental impact. By integrating energy-efficient technologies into their automation systems, AMS enables companies to operate more sustainably while maintaining high levels of productivity. This approach not only benefits the environment but also contributes to overall operational efficiency by reducing energy-related expenses.Flexible Manufacturing Systems

Flexibility is a key factor in achieving efficiency, especially in industries where production demands can change rapidly. AMS Factory Automation de Mexico offers flexible manufacturing systems that can be easily adapted to different products, processes, and production volumes. This flexibility allows manufacturers to quickly respond to market changes without the need for significant retooling or investment, thus maintaining efficiency even in the face of shifting demands.

The Impact on Manufacturing Efficiency

The impact of AMS Factory Automation de Mexico’s solutions on manufacturing efficiency is profound. By integrating advanced automation, robotics, and data analytics into their operations, manufacturers can achieve significant improvements in productivity, quality, and resource utilization. These enhancements lead to lower production costs, faster time-to-market, and a stronger competitive position in the global marketplace.

Moreover, the focus on energy efficiency and sustainability ensures that these gains are achieved in an environmentally responsible manner. As more companies prioritize sustainability, the ability to boost efficiency while reducing environmental impact becomes a critical advantage.

Conclusion

AMS Factory Automation de Mexico is making a substantial impact on manufacturing efficiency with its innovative automation solutions. By offering advanced robotics, integrated control systems, smart data analytics, and energy-efficient technologies, AMS is helping manufacturers optimize their operations and achieve new levels of productivity. As the manufacturing industry continues to evolve, AMS Factory Automation de Mexico will remain at the forefront of driving efficiency and excellence in industrial processes.

FAQs

Q1: What industries benefit the most from AMS Factory Automation de Mexico’s efficiency solutions?

A1: AMS Factory Automation de Mexico’s solutions are beneficial across various industries, including automotive, electronics, consumer goods, and more, helping each sector optimize its unique manufacturing processes.

Q2: How does AMS integrate automation and robotics to boost efficiency?

A2: AMS integrates advanced automation and robotics to automate repetitive tasks, reduce manual errors, and increase production speed, all while maintaining high levels of quality and consistency.

Q3: What role does data analytics play in improving manufacturing efficiency?

A3: Data analytics is crucial for improving efficiency by providing insights into production performance, resource utilization, and process bottlenecks, enabling manufacturers to make data-driven decisions that enhance productivity.

Q4: How does AMS support energy efficiency in manufacturing?

A4: AMS supports energy efficiency by designing automation systems that optimize energy usage, reduce energy costs, and minimize environmental impact, contributing to more sustainable and cost-effective manufacturing operations.